SPRING BOAT COMMISSIONING

BASED ON AN ARTICLE By Frank Lanier

Finally, it’s time to ready your boat for the upcoming season!

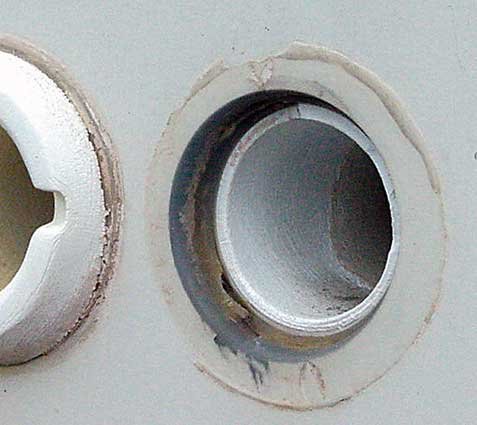

Check Those Thru-Hulls

Springtime is the right time to check each of your composite (plastic) thru-hulls for cracks and deterioration. Degradation due to ultraviolet light is the main culprit; however, stress caused by an unsupported hose bouncing around inside also can be a factor. Failure typically begins as a crack where the body of the thru-hull fitting joins the outer flange, often progressing until the flange simply falls off. Once that occurs, there’s nothing left to keep the thru-hull in place, meaning that it will eventually be pulled inboard, leaving a gaping hole. The thru-hull shown here was located near the waterline; the resulting hole reduced the vessel’s effective freeboard from feet to inches.

Inspect Your Hose Clamps

The devil is in the details, as this photo clearly shows. The owner failed to refit the hose clamps for the engine’s raw-water intake hose (which had been removed while winterizing the engine the previous fall). The loose hose slipped off soon after launch, partially sinking the vessel. Nothing helps more to reduce such slipups than a detailed checklist.

Inspect The Impeller On The Engine’s Raw-Water Pump

While impellers can last a number of years under normal operation, many boat owners simply replace them annually as cheap insurance against engine overheating due to wear and failure. A damaged impeller can cause severe overheating if not caught quickly, potentially leading to a smoking-hot hose in the engine space. Even if a failed impeller doesn’t melt an exhaust hose, those missing bits can become lodged in the cooling system, blocking passageways and further reducing engine-cooling ability. Once that occurs, you’ll need to disassemble the cooling system to remove these parts — another expense that can be easily avoided by swapping out the impeller before it fails.

Inspect The Bilge-Pump Float Switch

The automatic float switch pictured below will provide zero protection during the upcoming boating season. In fact, due to a leaky stuffing box and no boat-check visits by the owner, it’s failure almost resulted in the vessel sinking over the winter. Installation and operation of automatic bilge-pump switches (as well as the pumps themselves) should be checked as part of every spring-commissioning list.

Floating-arm-type switches must be securely mounted and installed clear of wires, hoses, and other obstructions that can impede operation of the switch arm. Orient the switch fore and aft, with the flapper pointed toward the stern. This is especially important on powerboats, as surging water during jackrabbit takeoffs can damage the flapper mechanism. Mounting the switch near the forward bulkhead of the bilge compartment will also help protect against surge damage.

Bellows Should Be Inspected Annually

The rubber bellows of your sterndrive plays a crucial role in maintaining your boat’s watertight integrity — unless it looks like the one above. Not all damage will be as obvious as this, however. Cracks and splits often occur within the folds of the bellows and may only be noticeable when the bellows is fully extended.

Check Shore-Power Cords, Plugs, And Receptacles

Most AC electrical fires occur when these overheat, so inspect them often. Loose or corroded connections generate heat and the potential for fire, a problem especially prevalent among vessels that continually run high-energy loads, such as air-conditioning, water heaters, and the like. Plugging and unplugging connectors while energized contributes to the problem. The micro-arcs and sparks generated each time you do so create tiny pits on surface connections, which in turn lead to resistance and heat buildup.

Continually Check For Corrosion And Get Rid Of It

Routine maintenance not only prolongs the service life of your equipment but can also keep you out of trouble. The corrosion on this battery post was so gnarly that it prevented the battery from charging, which kept the engine from starting and required the owner to call for a tow. He was (luckily) able to do this from his cellphone, because the dead battery also made his VHF radio useless.

Bad Hoses Cause Bad Things To Happen

In this case, the water in the cockpit always drained and everyone was happy — until a series of unfortunate events resulted in another at-the-dock sinking. Rain during a heavy downpour dumped gallons of water into the cockpit, which (due to the badly deteriorated hose) drained into the bilge rather than overboard. The vessel had no operational bilge pump, and the excess amount of bilge water caused the boat to settle, submerging the thru-hull and sinking the boat.

Corrosion Is Your Trailer’s Enemy

One insidious problem is corrosion inside a trailer’s axle tube as a result of trapped water. This can lead to a catastrophic failure of the axle — and it will never happen at a convenient time. Verify after each use that the axle is completely sealed or, if not, that it drains properly. In addition to the routine checks you do before each tow, you should regularly give your trailer a more in-depth maintenance inspection for problems such as bent or twisted members, nonfunctioning lights, cracked welds, missing hardware, and, of course, corrosion. To further hedge your bets while on the road, consider purchasing TRAILER ASSIST® offered by BoatUS.

Routinely Pull A Dipstick And Check Fluid Levels

When it comes to protecting your engine and transmission, there are few things simpler or easier. While there’s no set rule on how often it should be done (each time you start and stop is good), checking the oil and transmission fluid before starting your engine is a good habit to develop. If the owner of the scorched transmission shown below had checked his fluid level, he wouldn’t have had to raid the kid’s college fund to pay for repairs.

Hoses Have A Finite Life Span